|

||||||||

|

||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

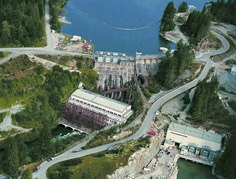

GM Shrum

Project Plant size - 2730 MW |

Flow Measurement Test at G.M. Shrum Powerplant with Acoustic Scintillation and Acoustic Time-of-Travel Methods

In 2016, flow comparison tests were conducted at the G.M. Shrum powerplant using both the Acoustic Scintillation (AS) and Time-of-Travel (ATT) methods. Repeat measurements were done at three different flows, with nominal power outputs of 185, 230 and 275 MW. The comparisons were conducted as a blind test for the AS method. BCH personnel filled the role of Chief of Test and operated the ATT instrument. The duration of the test at each setting was 20 minutes, during which time data were collected simultaneously on both flowmeters The comparison test indicated that the measurement uncertainty of the AS method is comparable to the uncertainty of the ATT method at ±1.0%. The test further indicated that the uncertainty of the AS measurement at the GMS units could be as low as 0.2%. That is certainly sufficiently accurate for the dispatch optimization. Publication: presented at IGHEM 2017 |

|

Kootenay Canal Project Plant size - 529 MW |

Acoustic Scintillation Flow Meter Successful in Flow Comparison Test at Kootenay Canal Power Plant Intake As part of an ongoing effort to advance the state-of-the-art of turbine flow measurement, CEATI (the Centre for Energy Advancement through Technological Innovation, Canada) sponsored comparison flow measurements at the intake of Unit #1 at B.C. Hydro's Kootenay Canal power plant, British Columbia, Canada, in October 2009. The measurements, supervised by the PTC-18 (ASME Performance Test Code committee 18), were run as a blind test, with none of the test participants having knowledge of the reference discharges until after the final results were submitted. The Acoustic Scintillation Flow Meter (ASFM) was one of the three intake flow measurement instruments tested. The other two methods deployed in the intake were current meters (Hydro Quebec) and acoustic time-of-flight (Accusonics). The reference measurement was provided by the acoustic time-of-flight method (Rittmeyer) deployed in a code approved location in a straight run of a penstock. The ASFM results demonstrated excellent accuracy (the average deviation from reference meter 0.44%), very good repeatability (one-sided 95% population confidence interval of 0.06%) and virtually no sensitivity to adjacent unit operation (1.1% at very low flows, 0% at medium flows and 0.07% at high flows). Based on these results, the PTC-18 considers the ASFM worthy of consideration for incorporation into the code. Publications: AQFlow authors - Hydro 2010, ASME performance test code committee papers - (1) Hydro 2010, (2) HydroVision 2011

|

|

In June 2000, during the acceptance tests for the two new Kaplan units with the penstock-installed acoustic time-of-travel flow meter, the ASFM was installed in the intake for comparison. Unfortunately, the wakes behind the major vertical trashrack support, located in the middle of the intake and very close to the measurement plane, produced a significant measurement bias, ranging from -2 to -6%. Since 2000, we have learned that such bias can be quantified with the help of vertically oriented measurement paths – this was done successfully under similar intake/trashrack configuration at the Chief Joseph power plant in 2008 and 2011. It is hoped that an opportunity to retest Stave Falls will materialize in the future.

|

|

|

Revelstoke

Project Plant size - 2480 MW |

In 1996, the ASFM was used at the intake of the Revelstoke power plant. Only a very limited amount of data was collected because of the problems experienced with the vibration of the ASFM mounting frame. Publication: presented at IGHEM1996 |