| Conditions of use

A) General

The ASFM has been developed specifically for the short, rectangular converging intakes typically found in plants with heads of 35 meters or less. However, the ASFM may be used at higher head plants when the intake characteristics comply with the requirements of this section. Because of the unstable inflow velocities or divergent approach angles likely existing in most intake measurement locations, both the magnitude and the direction of the velocities measured by the ASFM must be considered in the calculation of discharge.

A critical assumption of the ASFM measurement technology is that the intensity and spectral characteristics of the turbulence in the moving fluid are uniformly distributed along the acoustic transmission paths. Such turbulence is usually present downstream of trash racks with fine vertical members. The following site-specific intake characteristics must be considered individually:

- Variations in the size and shape of the trashrack structural supports upstream of the ASFM measurement plane, and their distance from the measurement plane.

- Variations in the uniformity and directionality of the inflow.

- Shape irregularities upstream and downstream of the measurement plane.

B) Intakes for which accurate results can be obtained directly

Experience has shown that the ASFM produces accurate and repeatable results when the following conditions are complied with:

-

Trash racks vertical structural supports are less than 100 mm in width or more than 6.0 m from the measurement plane and the trash racks have been cleaned prior to the testing.

-

The horizontal angle between the inflow velocity vector and the axis of the intake does not exceed 15 degrees, and the operation of the neighbouring units and the spillway, if applicable, is controlled to the degree necessary to remain within this limitation during the period required to perform the measurements.

-

Average flow velocities are between 0.5 and 8.5 m/s and measurement sections are wider

than 1.5 m.

-

There are no non-typical intake conduit shapes, particularly those that can result in recirculation. The presence of such irregularities must be investigated before starting the measurement.

-

Fish diversion screens upstream of the measurement plane will require special investigations.

-

There are no excessive air bubbles and/or acoustic noise. If their presence results in missed samples, enough valid samples must be obtained to be compatible with the assumptions used in the error analysis.

C) Intakes for which bias corrections will be required

For some intakes where the above requirements are not fulfilled, the systematic uncertainty of the measurement may be predicted before the measurement is started, and thus removed from the measurement results, as follows:

In a normal ASFM installation, the measurement paths are horizontal, and thus large vertical trash rack supports can introduce bias into the ASFM measurements. As illustrated in Fig. 4, the magnitude of the measurement bias is strongly dependent on the contrast between the turbulence of the intersecting vertical wakes and the turbulence within the remainder of the acoustic path, the distance between the measurement plane and the trash rack support and the width of the trash rack supports. If the wakes from the major horizontal trash rack supports (parallel to the acoustic paths) have merged before they reach the measurement plane, then it is very likely that the bias due to the wakes from the vertical support members will be reduced to a negligible amount. The distance downstream of the trash rack, Xmerge required for the wakes from the horizontal members to merge may be estimated as

where

H is the vertical separation between the major horizontal trash rack supports,

D is their width in the vertical and

X is the distance between the trash rack and the measurement plane (all dimensions in meters).

If the distance to the measurement section is less than Xmerge, an upper bound for the bias error due to wakes from the vertical members may be estimated using numerical calculations (Bouhadji et al. 2003) and comparisons with the available experimental data on similar structures (Wygnanski, I. J., Champagne, F., and Marasli, B. 1986. On the Large Scale Structures in Two-Dimensional, Small-Deficity, Turbulent Wakes. J.Fluid Mech. 168, 31-71 and Stewart, R. W., and A. A. Townsend, 1951. Similarity and self preservation in isotropic turbulence. Phil. Trans. Roy. Soc. London, A243, 359-386.)

Figure. 4: Illustration of the relation between wake merging and ASFM bias

Experience has shown that with these corrections the resulting systematic uncertainty of measurements with the ASFM can be within

±2% for many difficult intakes which do not comply with the requirements of paragraph B above. However, experience has also shown that there will be some exceptionally difficult intakes where no acceptable measurement uncertainties will be achievable.

Back to Top

Field Comparison Measurements

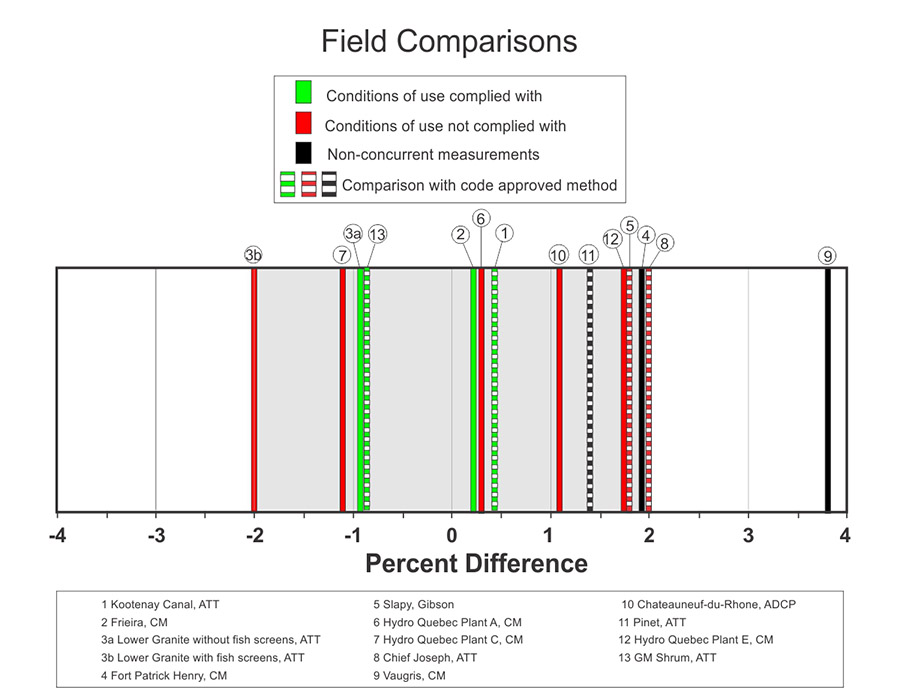

In order to verify the accuracy of the ASFM, a number of comparison measurements were carried out. Their results are shown graphically below, and further details of the individual measurements can be found under appropriate headings in the Technical Reports section (http://aqflow.com/reports.html).

It can be noted that when the conditions of use listed in previous paragraphs are complied with, all four ASFM results agree with the reference measurements within ±1%. Even when the conditions of use are not complied with, all ASFM results agree with the reference measurements within ±2.0% (±2.0% indicated by shaded area). The only measurement outside the ±2.0% limits was a non-concurrent measurement at Vaugris, France.

More comparative measurements are needed; several are already in the planning stages. Nevertheless, the results to-date prove that the accuracy of the ASFM is comparable to other established and code-accepted measurement methods. Consequently, they are currently being reviewed in detail by the IEC 60041 and ASME PTC-18 code committees as part of their respective processes of publication updating. The IEC code is scheduled for re-publication in 2018, the ASME code is scheduled for re-publication in 2018. The acoustic scintillation measurement method will be included in both of these codes.

|